Most consumers of electrical energy operate from a 220 V AC network. Still, many modern lighting devices require unique power supplies that provide a reduced AC or DC voltage or a stable current. To create the necessary operating conditions for low-voltage consumers, an electronic transformer, a power supply, a driver. It is essential to correctly determine which devices to choose in a particular situation because it depends on how well and how long the equipment will serve. Let’s consider the properties of each converter separately and how the driver differs from the power supply and transformer.

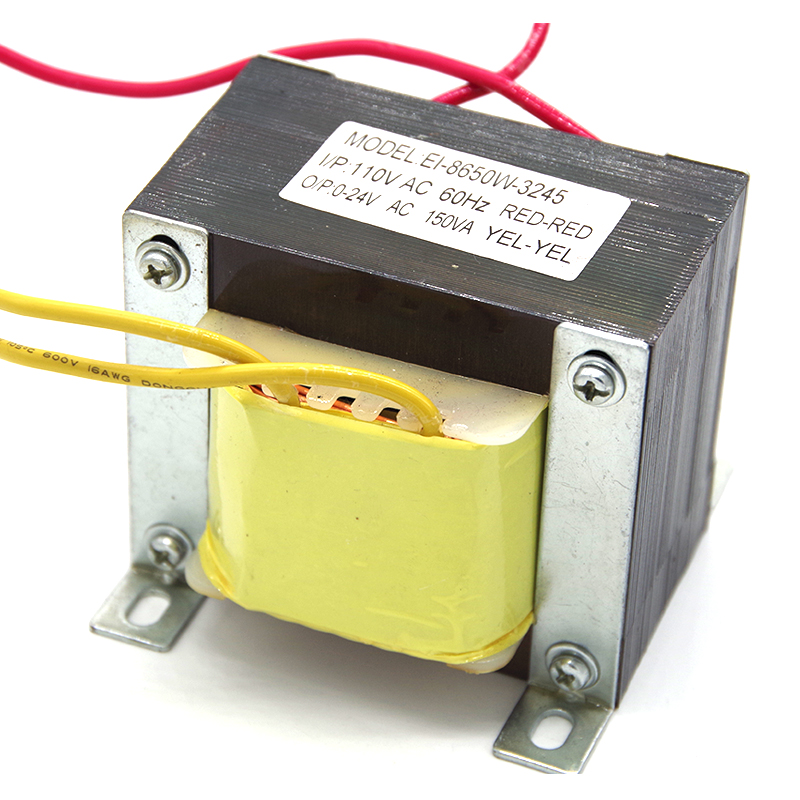

Electronic Transformer

The simplest power source is a transformer. Its functions include raising or lowering the mains voltage.

Electronic and conventional transformers have alternating current at the output, but what is the difference between them? Electronic work at a high frequency is significantly higher than the mains 50 Hz, namely tens of kilohertz. It made it possible to reduce their weight and dimensions. Electronic transformers use power 12 V or 24 V halogen lamps.

If you connect such bulbs directly to the electrical network, they will burn out. But, if the halogen lamp is rated for 220 V, then a step-down transformer is not needed. The device is connected directly to the network.

This type of converter is not suitable for LED lamps and luminaires. But the simplicity and low cost of the device allowed it to be widely used to connect halogen lamps.

When choosing a device, you must consider:

- Output voltage (must correspond to the rated value of the connected device).

- Rated power (if several halogen lamps are connected in parallel to the power source, the power of each is summed up).

Such an electronic converter is placed close to the powered light bulbs not to overheat, and natural ventilation is provided. When installing local lighting, it is allowed to mount it behind false ceilings, partitions, in cabinets. It is forbidden to turn on the transformer without load, and most models will not start simultaneously.

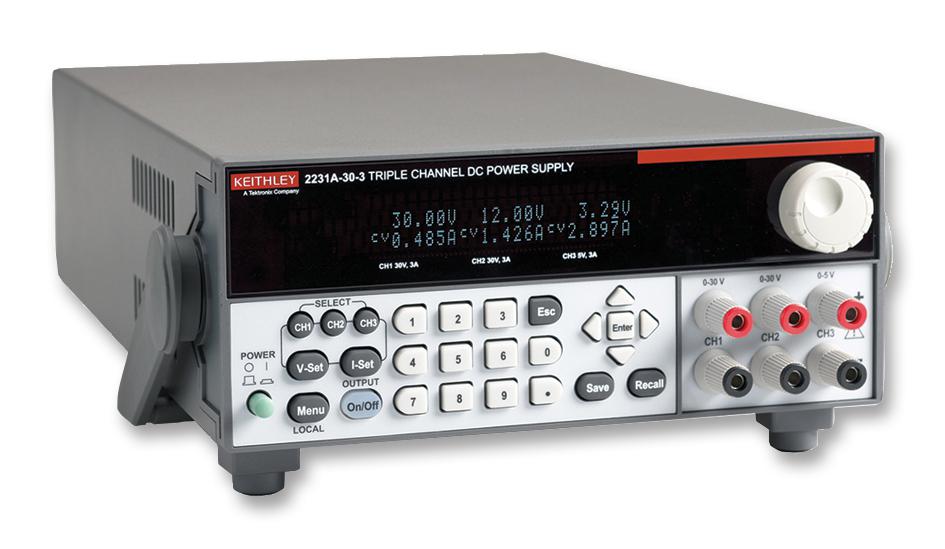

DC Power Supply

A DC power supply reduces AC voltage from the mains to the required value and converts it to DC.

Such power supplies are used for LED strips and 12V LED lamps. Using a transformer to power them would be a mistake, as this can reduce the lifespan and cause the light output to shine.

As you know, LEDs require a stable current to operate. But such power supplies only stabilize the voltage. For this, current-limiting resistors are used in the LED strip, for example. But such a solution is effective only for low-power diodes.

LED Driver

A driver is used to connect powerful LEDs used in spotlights, spotlights, street lamps.

This device is a constant current source. The voltage may change when a load connects, but the current strength will have a well-defined value.

Why is a driver used to connect the LEDs and not a power supply?

One of the characteristics of LEDs is voltage drop. Suppose there is an entry in the characteristics of a semiconductor device – 300 milliamperes and 3.3 volts. In that case, this means that the nominal current for the device is 300 mA, and the voltage drop is 3.3 V. If you supply it with a stabilized current of this magnitude, it will serve for a long time and shine brightly.

From the graph of the current-voltage characteristic, it can seem that even a slight increase in voltage will lead to a noticeable increase in current. And this is not a directly proportional relationship but an approximate quadratic one.

One would assume that by setting the exact voltage once, it would be possible to permanently fix the value of the nominal current required for the operation of the LED light source. But each instance has unique parameters and properties, and when connecting several pieces in parallel or series, the result will be unpredictable.

In addition, they influence by the ambient temperature. The fact is that LEDs have a negative temperature coefficient of voltage (TKN). It means that when heated, the drop across the LED decreases, and the current increases if a stabilized, constant voltage is applied. The output voltage changes depending on the load and its state for drivers, and the current is stabilized.

Therefore, if you use a regular 12V power supply when connecting the LED, the lamp will work, reducing the period. To choose the right driver, you need to take into account its main technical characteristics:

- Rated output current.

- Maximum power.

- Minimum power.

Sometimes the parameters for the device are specified in a different form. For example, the technical characteristics of the driver 18-34V 650mA (20W):

- Input voltage 85-277 V.

- Output voltage 18-34 V.

- Output current 650 mA.

It is suitable for an LED matrix with the following characteristics: power – 20 W, voltage – 18-34 V, operating current – 650-700 mA, or 6-10 LEDs with a power of 2 W.

LED lamps are connected to the driver in series since the same current will flow through all the elements. If they connect parallel, it may turn out that one of the elements will be overloaded, while the other will not work at total capacity.

To not exceed the maximum permissible load of the converter, it is not recommended to increase the number of LEDs in the circuit.

The choice of the driver is carried out according to the current that the LEDs consume. For example, a diode with a power of 1 W needs 300 – 350 mA.

This type of power supply has such disadvantages as:

- Narrow specialization in LEDs.

- The ability to use only for a certain number of LED sources.

That is, a certain number of LEDs are selected for each device. If one fails during operation, the circuit will break, and the driver will go into protection (or burn out) since the latter does not work in idle mode.

In conclusion, even though the driver, power supply, and electronic transformer are used to connect low-voltage consumers, we note that these are entirely different devices, differing from each other in purpose. It is crucial to understand in which cases each of them applies. After all, only an adequately selected power supply can create optimal operating conditions for your equipment.